Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

Welding is a critical skill in various industries, from construction to automotive repair, and the right welding tools can dramatically influence the quality and efficiency of the work. According to the American Welding Society, the demand for skilled welders is projected to grow by 6% from 2019 to 2029, making it essential for beginners to familiarize themselves with the essential welding tools and their applications. Understanding the different types of welding equipment, their features, and best practices can significantly enhance a beginner's capability to produce strong, reliable welds. In this comprehensive guide, we will delve into the secrets of welding tools, offering insights and advice that will empower novice welders to navigate the complexities of this vital craft with confidence.

Understanding the Different Types of Welding Tools and Their Uses

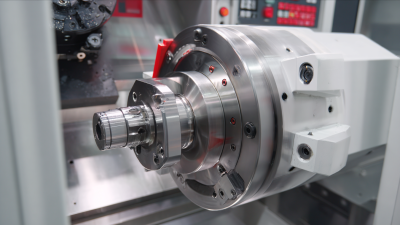

Welding is a versatile skill that requires an understanding of various tools to get started. Among the primary types of welding tools, a welder’s machine is essential. Common varieties include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welders. MIG welders are popular for beginners due to their user-friendly operation and versatility in welding different metals. TIG welders, although requiring more skill, offer precision for intricate work, while Stick welders are known for their portability and effectiveness in outdoor conditions.

In addition to welding machines, equipment like welding helmets and protective gear play a vital role in ensuring safety. A quality welding helmet protects the welder’s face and eyes from harmful UV rays and sparks, while gloves and aprons shield the body from heat and molten metal. Other important tools include angle grinders for surface preparation, clamps to hold materials in place, and wire brushes for cleaning the weld joints. Understanding these tools and their specific functions will lay a solid foundation for any beginner looking to excel in the art of welding.

Essential Safety Gear for Beginner Welders: What You Need to Know

When embarking on a welding journey, understanding the essential safety gear is paramount. According to the American National Standards Institute (ANSI), over 50,000 injuries related to welding occur annually in the United States alone, highlighting the critical need for proper safety equipment. Beginners must equip themselves with personal protective equipment (PPE) that includes a welding helmet with a proper shade lens, gloves designed specifically for welding, flame-resistant clothing, and sturdy footwear. Each piece plays a vital role in safeguarding against intense heat, UV radiation, and potential sparks.

The Occupational Safety and Health Administration (OSHA) emphasizes that wearing adequate safety gear can significantly reduce the risk of serious injury. For instance, the right welding helmet not only protects the eyes from harmful rays but also shields the face from burns, while flame-resistant clothing prevents ignition from stray sparks. Statistics reveal that without proper protection, welders are three times more likely to experience severe injuries. Therefore, investing in quality safety gear is not just a recommendation but a necessity for anyone eager to start welding safely and effectively.

Essential Safety Gear for Beginner Welders

Step-by-Step Guide to Setting Up Your Welding Workspace Effectively

Setting up an effective welding workspace is crucial for both safety and productivity. First, ensure adequate ventilation. According to the American National Standards Institute (ANSI), proper ventilation can reduce exposure to harmful fumes by up to 40%. A well-ventilated area helps maintain air quality, allowing welders to work comfortably and safely.

Next, organize your tools and materials efficiently. Use a designated tool chest for your welding equipment and keep materials within arm's reach to minimize downtime. According to a report from the American Welding Society (AWS), an organized workspace can improve workflow by over 20%. Consider utilizing magnetic tool holders and proper storage bins to maintain an orderly setup.

**Tips:** Always wear appropriate personal protective equipment (PPE) such as helmets, gloves, and aprons, as these are essential for safeguarding against sparks and heat. Additionally, keep a fire extinguisher accessible and ensure your workspace is free from flammable materials to prevent hazards. Adhering to these practices not only enhances safety but also fosters a more efficient welding environment.

Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

| Tool Type | Description | Essential Features | Typical Uses |

|---|---|---|---|

| MIG Welder | A welding machine that uses a continuous wire feed and shielding gas. | Continuous wire feed, adjustable voltage, gas mixing. | Sheet metal, automotive, and repair work. |

| TIG Welder | A high-precision welder using a non-consumable tungsten electrode. | Non-consumable electrode, foot pedal control, inert gas protection. | Thin metals, pipes, and art projects. |

| Stick Welder | A versatile welder that uses consumable electrodes to create welds. | Portable, works in windy conditions, simple setup. | Outdoor welding, heavy metals, and repair work. |

| Plasma Cutter | A tool that uses a high-velocity jet of ionized gas to cut through metals. | High precision, fast cutting speed, minimal heat affected zone. | Metal fabrication, art, and repairs. |

| Safety Gear | Protective equipment to shield the welder from hazards. | Welding helmet, gloves, flame-resistant clothing. | Essential for all welding tasks to ensure safety. |

Tips for Choosing the Right Welding Technique for Your Project

Choosing the right welding technique for your project is crucial for achieving strong and durable joints. Each welding method offers unique advantages that can significantly impact the outcome of your work. For beginners, it's essential to consider the type of material you will be welding, as this will largely dictate the technique you should use. For example, MIG welding is versatile and ideal for thin materials, while TIG welding is better suited for more delicate projects requiring precision and control.

Additionally, understanding the specific requirements of your project can help you narrow down your options. If you are working on outdoor projects with thicker materials, stick welding may be the preferred choice due to its resistance to wind and contamination. On the other hand, if you require a clean finish with minimal cleanup, consider opting for TIG welding. Always remember to prioritize safety and acquire the necessary skills through practice and training, as mastering the right technique will ultimately enhance the quality and longevity of your welds.

Basic Maintenance and Care for Your Welding Tools to Ensure Longevity

Maintaining and caring for your welding tools is essential to ensure their longevity and optimal performance. Regular cleaning is a fundamental step—after each use, remove any spatter or residue from the welding process. This not only keeps your tools in good shape but also prevents contamination that could affect future welding projects. Use appropriate solvents and brushes designed for the materials you are working with.

When it comes to your welding electrodes, storage plays a crucial role. Keep them in a dry, airtight container to prevent moisture absorption, which can compromise their effectiveness. Rotating your inventory is also a good practice; use older electrodes first to ensure they do not sit unused for too long.

Tips: Always inspect your equipment before and after each use. Look for signs of wear or damage, such as frayed cables or cracked nozzles, and address these issues promptly. Additionally, invest in quality maintenance products that are compatible with your tools to enhance their lifespan and performance. Keeping a maintenance schedule can help you stay organized and proactive in caring for your welding tools.

Related Posts

-

Innovative Techniques in Sheet Metal Manufacturing You Might Not Know

-

7 Best Laser Machine Innovations to Transform Your Manufacturing Process

-

Exploring Alternatives to CNC Laser Cutting Machines for Precision Manufacturing

-

10 Best Sheet Metal Prototyping Tips for 2023 to Boost Your Production Efficiency

-

Ultimate CNC Machine Showdown Unveiling the Best Options for Your Manufacturing Needs

-

Exploring CNC Turning Innovations at the 138th Canton Fair in 2025

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms