Ultimate Guide to Mastering Metal Stamping Techniques for Your Business

In the fast-paced world of manufacturing, mastering metal stamping techniques is essential for businesses looking to enhance productivity and deliver high-quality products. Metal stamping, a process used to shape and cut metal sheets into precise designs, can significantly impact efficiency and cost-effectiveness in production lines. This ultimate guide will navigate you through the various methodologies, tools, and best practices involved in metal stamping, ensuring that you gain a comprehensive understanding of the process. Whether you're a seasoned professional or just starting your journey in the metalworking industry, this blog will provide you with actionable insights and techniques that can elevate your business operations. Prepare to explore the transformative potential of metal stamping and how effectively harnessing these techniques can lead to remarkable results for your operations.

Essential Metal Stamping Techniques Every Business Should Know

Metal stamping is an essential process for many businesses looking to produce high-quality parts efficiently. Among the fundamental techniques every business should know, progressive die stamping stands out due to its ability to create complex shapes in a single pass. This method allows for the production of a variety of components while minimizing waste, resulting in cost-effective manufacturing. Understanding how to set up and maintain progressive dies can significantly enhance production speed and precision, setting your business apart from the competition.

Another crucial technique is blanking, where metal sheets are precisely cut into desired shapes. This technique is vital for creating parts that require high accuracy and uniformity. Additionally, mastering the art of deep drawing can enable businesses to produce deeper, more intricate components without sacrificing material integrity. By investing time in mastering these metal stamping techniques, businesses can streamline their operations, improve product quality, and ultimately increase profitability in a competitive landscape.

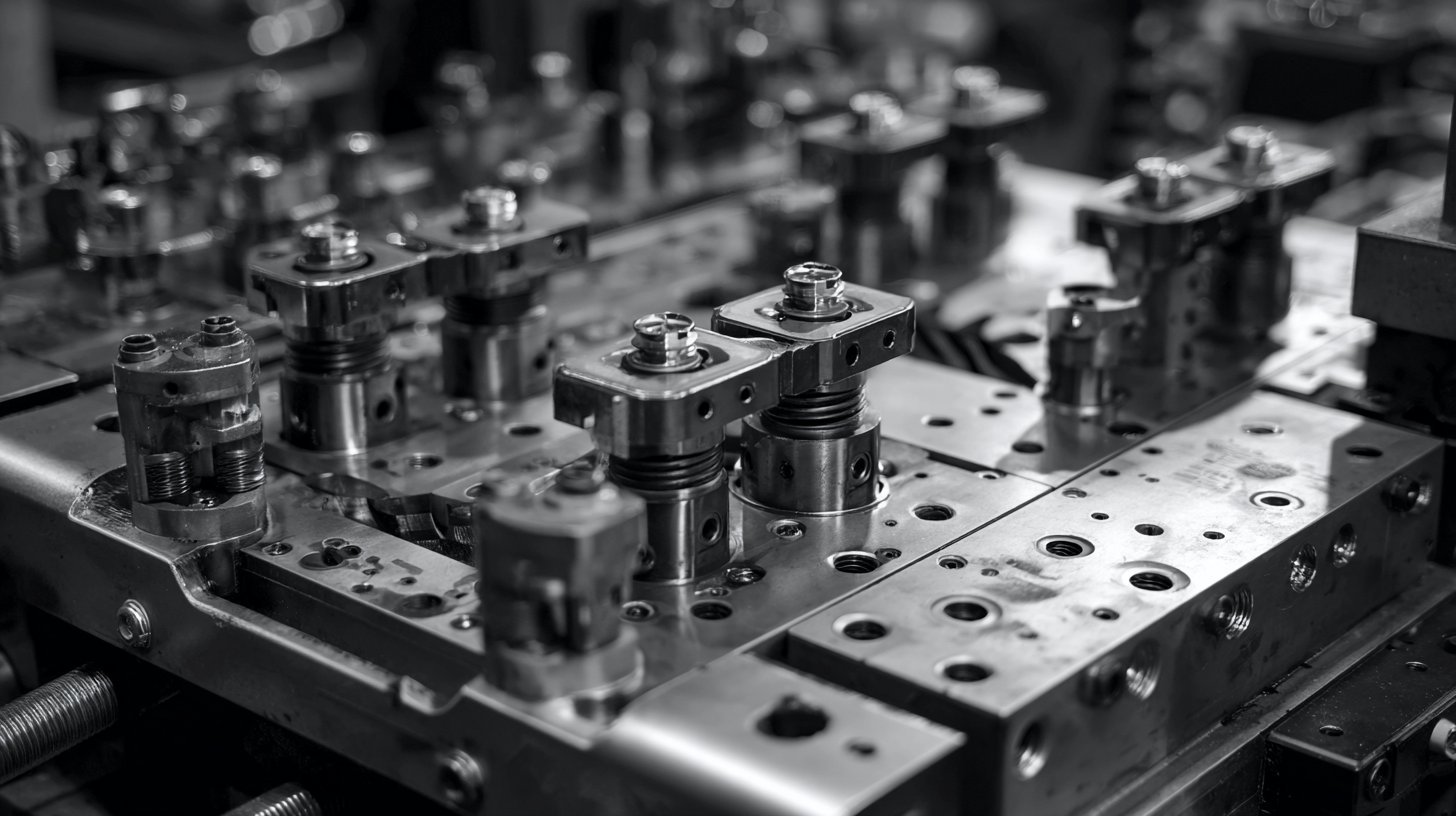

Innovative Tools and Equipment for Enhanced Metal Stamping Efficiency

In the ever-evolving landscape of metal stamping, leveraging innovative tools and equipment can significantly enhance efficiency and productivity in your business. Advanced machinery, such as servo-driven presses, offers precision control over stamping processes, allowing for faster cycle times and reduced scrap rates. These presses can adapt to various materials and thicknesses, making them a versatile choice for manufacturers looking to streamline operations.

Additionally, incorporating automation and tooling systems helps minimize manual interventions and errors. Automated feeding and part handling systems can optimize workflow, reducing downtime while increasing throughput. Investing in high-quality dies and tooling not only ensures longer tool life but also maintains the consistency needed for high-volume production. By embracing these innovative technologies, businesses can achieve remarkable improvements in their metal stamping processes, ultimately leading to higher quality products and greater customer satisfaction.

Understanding Material Selection for Optimal Stamping Results

Choosing the right material is crucial for achieving optimal results in metal stamping. Different metals possess unique properties that can significantly influence the stamping process and the final product's quality. For instance, aluminum is light and corrosion-resistant, making it ideal for automotive and aerospace applications. Conversely, steel, known for its strength and durability, is often used in construction and heavy machinery. Understanding the characteristics of each material allows businesses to select the one that best meets their production needs and desired specifications.

In addition to the type of metal, thickness and hardness also play vital roles in the stamping process. Thicker materials may require more powerful presses and specialized dies, while harder metals might necessitate additional tooling considerations. It's essential to assess the specific requirements of the project, including tolerances and batch sizes, to determine the most appropriate material for stamping. By carefully selecting materials based on these factors, businesses can optimize their stamping operations, reduce waste, and enhance the overall efficiency of their production lines.

Ultimate Guide to Mastering Metal Stamping Techniques for Your Business

| Material Type | Thickness (mm) | Tensile Strength (MPa) | Elongation (%) | Best Use |

|---|---|---|---|---|

| Steel | 1.0 | 400 | 20 | Automotive Parts |

| Aluminum | 0.8 | 270 | 30 | Electronic Housings |

| Brass | 1.2 | 310 | 15 | Plumbing Fittings |

| Stainless Steel | 1.5 | 520 | 40 | Food Processing Equipment |

| Copper | 0.6 | 210 | 25 | Wiring and Connectors |

Common Challenges in Metal Stamping and How to Overcome Them

Metal stamping is a vital process for many manufacturing sectors, but it comes with its share of challenges. One significant challenge is the high rate of scrap material generated during production. According to a report by the Precision Metalforming Association, nearly 30% of materials used in metal stamping operations become waste. This not only increases costs but also impacts sustainability efforts. To combat this, businesses can invest in precision tooling and advanced software that optimize the stamping process, significantly reducing scrap rates.

Another common issue is achieving consistent quality in stamped parts. Variations in material properties or environmental factors can lead to defects that compromise the integrity of the final product. Research from the National Institute of Standards and Technology indicates that implementing strict quality control measures and utilizing statistical process control can improve product consistency by up to 25%. Businesses that embrace these strategies will not only enhance their competitiveness but also build stronger relationships with clients, who increasingly demand reliability and quality assurance in their supply chains.

Ultimate Guide to Mastering Metal Stamping Techniques

This chart illustrates the common challenges faced in metal stamping along with their impact on production efficiency. The vertical axis represents the percentage of impact on efficiency, while the horizontal axis shows various challenges.

Future Trends in Metal Stamping: What Businesses Need to Prepare For

As the metal stamping industry evolves, staying ahead of future trends is crucial for businesses aiming to maintain a competitive edge. One of the most significant trends is the increasing integration of automation and robotics in the stamping process. This not only enhances precision but also significantly speeds up production times, allowing businesses to meet growing demand without sacrificing quality. Companies that invest in smart technology and automated solutions can streamline operations and reduce labor costs, setting themselves apart in a crowded marketplace.

Another emerging trend is the focus on sustainability and eco-friendly practices. As regulatory standards become more rigorous and consumers lean towards environmentally responsible products, the metal stamping industry must adapt. Businesses should explore the use of renewable materials, efficient energy practices, and waste reduction strategies in their manufacturing processes. By prioritizing sustainability, companies can not only reduce their environmental footprint but also appeal to a growing segment of eco-conscious consumers looking for responsible brands.

Embracing these trends will not only future-proof businesses in the metal stamping sector but also open new avenues for growth and innovation.

Related Posts

-

Top Strategies for Enhancing Efficiency in Sheetmetal Fabrication Processes

-

Innovative Techniques in Sheet Metal Manufacturing You Might Not Know

-

Ultimate CNC Machine Showdown Unveiling the Best Options for Your Manufacturing Needs

-

Exploring Alternatives to CNC Laser Cutting Machines for Precision Manufacturing

-

Mastering the Craft of Structural Steel Fabrication A Step by Step Tutorial

-

5 Best Tips for Maximizing Efficiency with CNC Fiber Laser Cutting Machines

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms