Top 10 Essential Tips for Mastering Stainless Steel Welding Techniques

Welding stainless steel is a skill that requires precision, knowledge, and practice to master. As one of the most versatile materials in manufacturing and construction, stainless steel provides a unique set of challenges and opportunities for welders. From its resistance to corrosion to its aesthetic appeal, understanding the nuances of stainless steel welding is essential for anyone looking to excel in this field. In this guide, we will explore the top ten essential tips that can help both novice and experienced welders enhance their techniques and achieve superior results.

Proper technique and attention to detail are crucial when working with stainless steel, as the material's unique properties can significantly affect the outcome of a weld. Factors such as heat control, electrode selection, and joint preparation play vital roles in the welding process. By mastering these key elements, welders can not only improve the quality of their work but also increase efficiency and safety in the welding environment. Throughout this article, we will discuss practical strategies and expert insights that will empower you to refine your stainless steel welding skills and elevate the quality of your projects. Whether you are working on small fabrications or large industrial components, these tips will prove invaluable in helping you navigate the complexities of stainless steel welding with confidence.

Understanding the Basics of Stainless Steel Welding

Stainless steel welding requires a solid understanding of its unique properties and the techniques best suited for working with this versatile metal. The essential characteristic of stainless steel is its resistance to corrosion, which is a result of its chromium content. When welding stainless steel, it is crucial to maintain the integrity of this protective layer, as damage can lead to corrosion and weaken the structure. Understanding the different grades of stainless steel and their specific welding requirements is fundamental for achieving strong and reliable welds.

To master stainless steel welding, one must also grasp the importance of the welding process selection. Processes such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) are commonly used for stainless steel due to their ability to produce clean, high-quality welds. It is essential to control the heat input during welding to avoid warping and distortion. Moreover, pre-weld cleaning and proper joint design significantly influence the quality of the weld. By becoming familiar with these factors, welders can improve their proficiency and produce durable, aesthetically pleasing welds that meet industry standards.

Choosing the Right Equipment and Materials for Welding

When it comes to stainless steel welding, selecting the right equipment and materials is crucial for achieving high-quality results. The American Welding Society reports that improper equipment selection can lead to a 20-30% increase in labor costs due to rework and material waste. For stainless steel, it is vital to choose a welding machine that can handle the specific types of stainless steel being used, whether it be austenitic, ferritic, or duplex grades. MIG or TIG welding processes are typically recommended for stainless steel due to their precision and ability to create clean welds without contaminating the joint.

In addition to the equipment, the choice of filler material plays a significant role in the welding process. The National Center for Biotechnology Information highlights that using the correct filler rod can improve corrosion resistance and overall joint strength by up to 40%. It is essential to match the filler material with the base metal composition to ensure compatibility and optimal performance. Furthermore, investing in high-quality shielding gas, such as argon or a mixture of argon and carbon dioxide, can enhance the weld quality and reduce defects. Ensuring these components are properly aligned can dramatically affect the efficiency and effectiveness of stainless steel welding operations.

Top 10 Essential Tips for Mastering Stainless Steel Welding Techniques

| Tip Number | Description | Recommended Equipment | Material Type | Common Applications |

|---|---|---|---|---|

| 1 | Clean the Surface Thoroughly | Wire Brush, Grinder | 304 Stainless Steel | Food Industry Equipment |

| 2 | Use Appropriate Filler Material | Stainless Steel Filler Rods | 316 Stainless Steel | Marine Applications |

| 3 | Select the Right Welding Process | TIG Welder, MIG Welder | Duplex Stainless Steel | Piping and Tubing |

| 4 | Control Heat Input | Arc Welder, Digital Thermometer | 430 Stainless Steel | Automotive Exhaust Systems |

| 5 | Maintain Proper Gas Flow | Argon Gas Cylinder | Nickel Alloy Stainless Steel | Chemical Processing Plants |

| 6 | Practice Proper Joint Design | Welding Jigs | 202 Stainless Steel | Construction Frameworks |

| 7 | Ensure Adequate Preheating | Heating Torch | 321 Stainless Steel | Aerospace Components |

| 8 | Inspect Welds Carefully | Ultrasonic Tester | 17-4 PH Stainless Steel | Pressure Vessel Construction |

| 9 | Use Back Purging Techniques | Inert Gas Back Purging Setup | Alloyed Stainless Steel | Heat Exchanger Manufacturing |

| 10 | Continuously Upgrade Skills | Welding Courses, Online Seminars | Various Stainless Grades | General Fabrication |

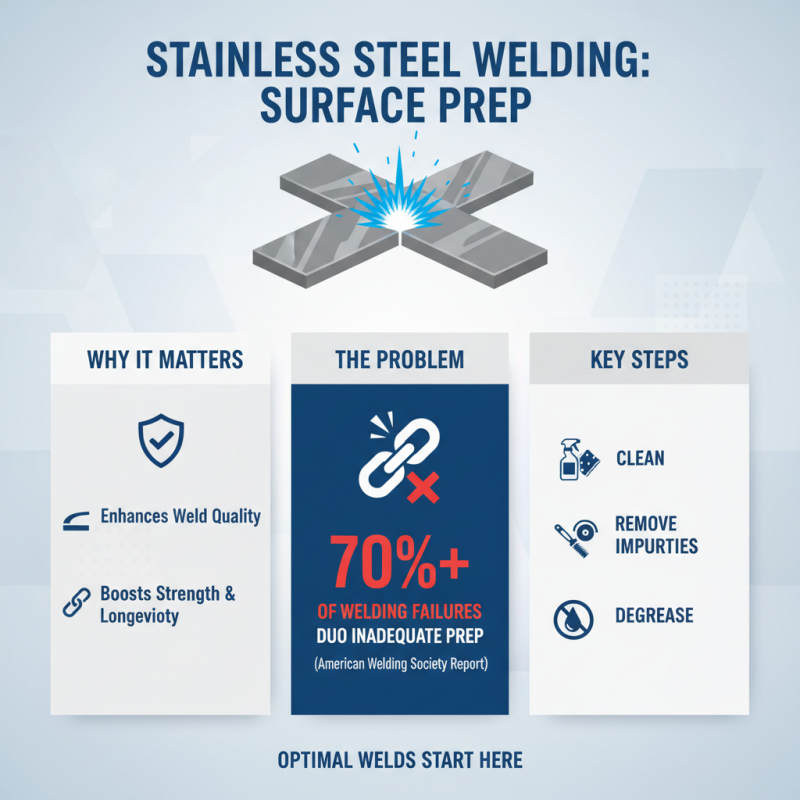

Techniques for Preparing Stainless Steel Surfaces

Preparing stainless steel surfaces is a critical step in ensuring optimal results in stainless steel welding. Effective surface preparation not only enhances weld quality but also significantly contributes to the longevity and strength of the final product. According to a report by the American Welding Society, nearly 70% of welding failures can be traced back to inadequate surface preparation, emphasizing the importance of this initial phase.

To achieve clean surfaces, it is essential to remove contaminants such as grease, oil, and oxidation. Methods commonly utilized include chemical cleaning agents and mechanical processes such as grinding or sanding. The National Association of Corrosion Engineers highlights that removing surface imperfections and contaminants can improve corrosion resistance by up to 40%. Additionally, the use of abrasive materials should be approached with caution; fine-grit abrasives are generally preferred to avoid introducing deep scratches that could serve as stress risers.

Furthermore, proper alignment and fitting of stainless steel components can prevent distortion and misalignment during the welding process. Techniques such as tacking and using fixtures can help maintain proper positioning. According to the Welding Journal, projects that implement stringent preparation protocols report a 20% increase in productivity and a significant reduction in rework costs. Proper preparation is thus not only vital for weld integrity but also for overall project efficiency.

Common Welding Techniques for Stainless Steel

When it comes to welding stainless steel, mastering the common techniques is crucial for achieving strong, durable joints. Among the most widely used methods are Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW). According to a recent report by the American Welding Society, GTAW, commonly known as TIG welding, is often preferred for its ability to produce high-quality welds on thin materials, offering precision that is essential in applications like aerospace and automotive industries. The process enables welders to control the heat input effectively, reducing the risk of warping or melting the base material.

On the other hand, GMAW, or MIG welding, stands out for its efficiency and speed, particularly when working with thicker stainless steel sections. This method allows for a continuous feed of filler material, making it suitable for projects with a high production rate. The number of stainless steel applications utilizing GMAW has seen a steady increase, with industry reports indicating growth of approximately 15% in the last five years due to its adaptability in various settings, including construction and manufacturing. Understanding these techniques and their applications is essential for welders aiming to enhance their skill set in stainless steel welding, ensuring they meet industry standards and demands for quality and efficiency.

Tips for Achieving Strong, Clean Welds in Stainless Steel

When welding stainless steel, achieving strong and clean welds is paramount for both structural integrity and aesthetic appeal. One of the most critical factors to consider is the selection of proper filler materials. Using the correct filler metal not only ensures compatibility with the base material but also helps in achieving a corrosion-resistant weld. Additionally, maintaining a clean working environment is essential; any contaminants on the stainless steel's surface can lead to defects such as porosity and discoloration. Before starting, thoroughly clean the surfaces to remove oils, dust, and other impurities.

Another important tip is to control the heat input during the welding process. Excessive heat can cause distortion and weaken the weld joint, while too little heat may result in inadequate fusion. It's advisable to use a method that allows for precise control over the heat, such as TIG welding, as it provides better arc stability and minimal spatter. Furthermore, employing proper welding techniques, such as using the right travel speed and maintaining a consistent arc length, will ensure that the weld penetrates sufficiently without burning through the material. This attention to detail not only results in strong joints but also in a clean finish that requires less post-weld cleaning and finishing work.

Related Posts

-

“Mastering Stainless Steel Welding Techniques: Tips for Flawless Joints and Durability”

-

Understanding the Advantages of MIG Welders in Modern Fabrication Processes and Their Impact on Industry Efficiency

-

Why Choosing the Right Welding Tools is Essential for Every DIY Project

-

7 Best Laser Machine Innovations to Transform Your Manufacturing Process

-

Exploring CNC Turning Innovations at the 138th Canton Fair in 2025

-

Unlocking Growth Opportunities for CNC Fiber Laser Cutting Machines at the 138th Canton Fair in 2025

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms