Exploring CNC Turning Innovations at the 138th Canton Fair in 2025

The 138th Canton Fair in 2025 promises to be a pivotal event for industries focused on manufacturing and innovation, particularly in the realm of CNC turning technologies. As one of the largest trade exhibitions in China, the fair will showcase the latest advancements in CNC turning machinery, attracting professionals and enthusiasts eager to explore cutting-edge solutions that enhance precision and efficiency in production. The significance of CNC turning in modern manufacturing cannot be overstated, as it plays a crucial role in the creation of intricate parts and components across various sectors. Attendees will have the opportunity to engage with industry leaders, discover new tools, and exchange knowledge on best practices, ultimately driving the evolution of CNC turning processes. This event not only highlights the advancements in technology but also reflects the growing importance of innovation in maintaining competitive advantages in the global market.

Innovative CNC Turning Technologies: Trends at the 138th Canton Fair

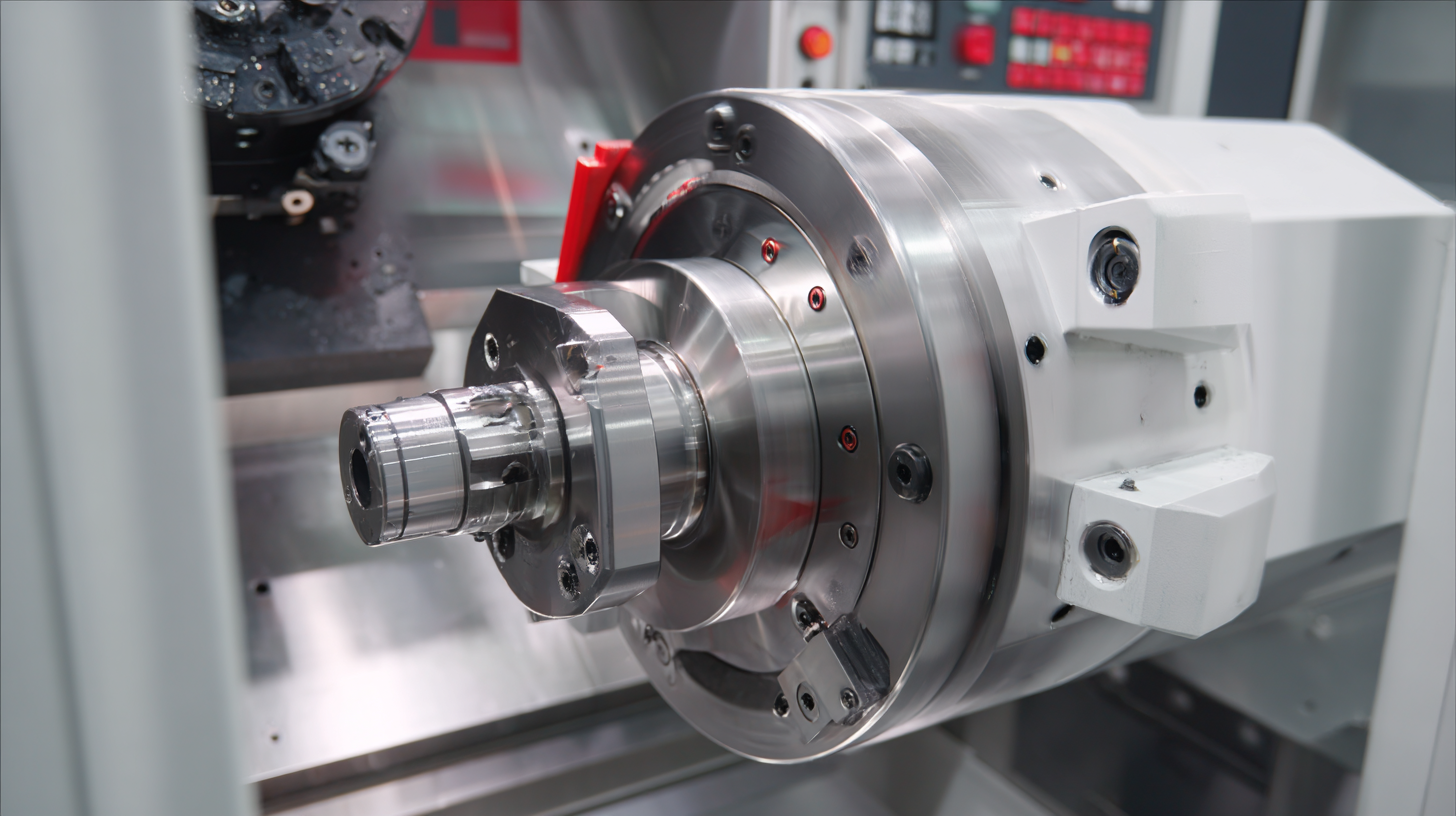

The 138th Canton Fair in 2025 showcased a plethora of innovative CNC turning technologies that are set to transform manufacturing processes. With advances in automation and precision engineering, manufacturers are embracing intelligent CNC turning solutions that drastically reduce production times while enhancing quality. Notably, the integration of artificial intelligence in CNC systems allows for real-time monitoring and adjustments, leading to optimal performance and minimal waste.

Emerging trends highlighted at the fair included the rise of multi-tasking CNC machines that combine turning, milling, and drilling capabilities into one integrated system. This versatility enables manufacturers to streamline operations and reduce floor space requirements. Furthermore, the incorporation of advanced materials and coatings in cutting tools was a focal point, promising increased durability and efficiency. As manufacturers seek to stay competitive in a rapidly evolving industry, these innovations signify a shift towards more sustainable and efficient production methods in CNC turning technology.

The Role of CNC Turning in Driving Manufacturing Efficiency in 2025

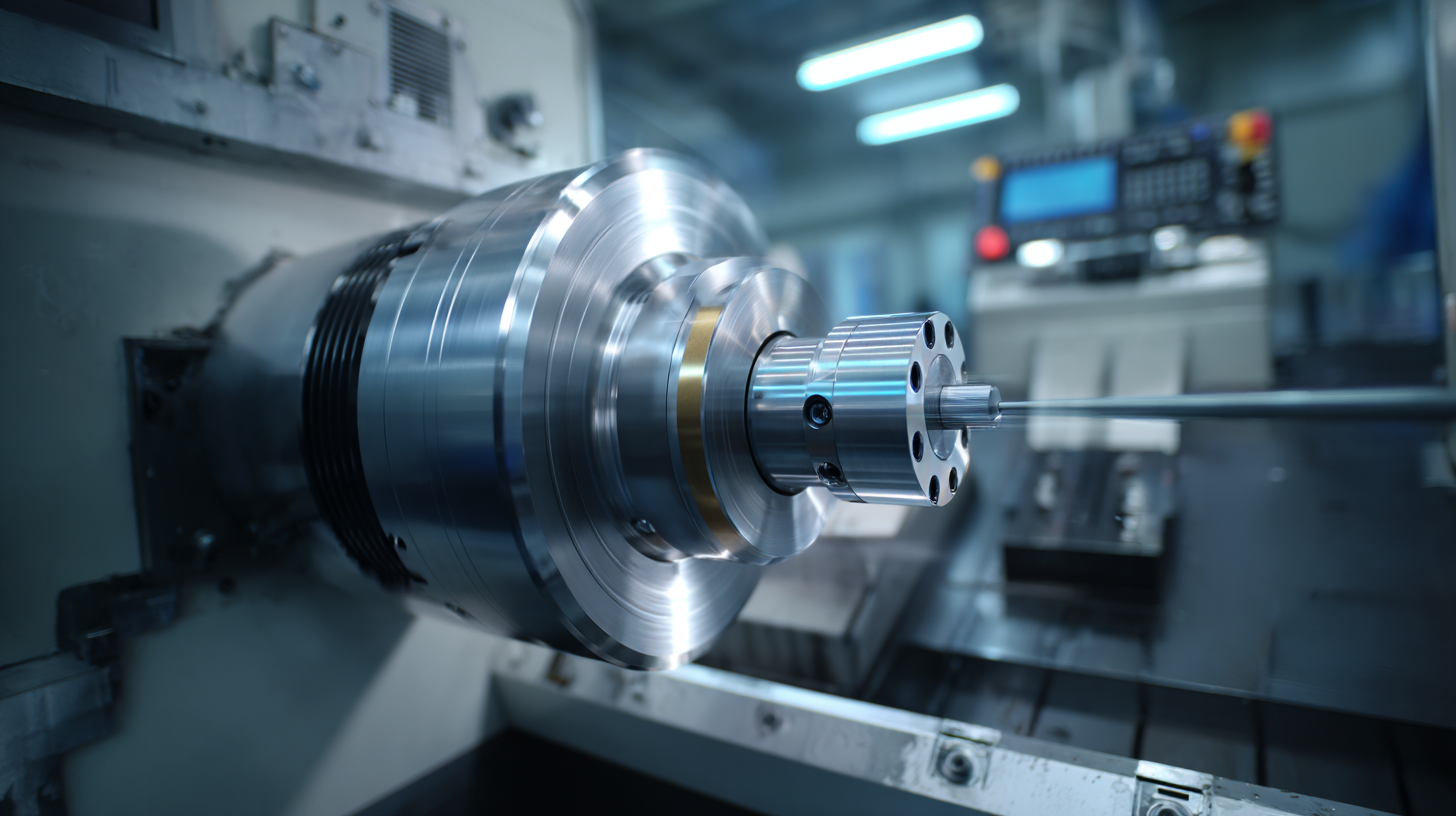

The integration of CNC turning technology in 2025 is set to revolutionize the manufacturing landscape by enhancing operational efficiency. According to a recent study by Industry Analytics, the global CNC machine market is expected to reach $117 billion by 2026, driven largely by increased automation and digitalization in manufacturing processes. CNC turning allows for high precision and repeatability, which in turn reduces waste and production costs. In addition, manufacturers are adopting predictive maintenance skills—with a 25% reduction in downtime reported in facilities utilizing CNC turning technologies.

For manufacturers attending the 138th Canton Fair, embracing advanced CNC turning solutions can provide a significant competitive edge. Investing in this technology not only streamlines production but also increases the overall quality of products. A report from the Manufacturing Institute found that companies implementing CNC turning have seen productivity gains of up to 30%.

Tips for companies looking to adopt CNC turning include focusing on upskilling workforce training and adopting smart technology integrations. Additionally, actively assessing the return on investment for CNC machine upgrades will help manufacturers make informed decisions that align with their production goals.

Key Players in the CNC Turning Market Showcased at the 138th Canton Fair

The 138th Canton Fair in 2025 serves as a pivotal platform for showcasing key players in the CNC turning market. This event attracts a myriad of manufacturers and innovators, reflecting the dynamic evolution within the industry. Companies renowned for their cutting-edge technologies and precision engineering presented their latest CNC turning solutions, emphasizing advancements that promise to revolutionize manufacturing processes.

Among the notable exhibitors, several firms highlighted their commitment to sustainability and efficiency. These players revealed innovative CNC turning machines integrated with smart technologies, allowing for improved automation and reduced operational costs. Additionally, they showcased user-friendly interfaces and advanced software that enhance production capabilities. The fair provided an invaluable opportunity for networking, enabling industry stakeholders to exchange ideas and explore potential collaborations that could shape the future of CNC turning operations around the globe.

Emerging Applications of CNC Turning in Various Industries: A 2025 Perspective

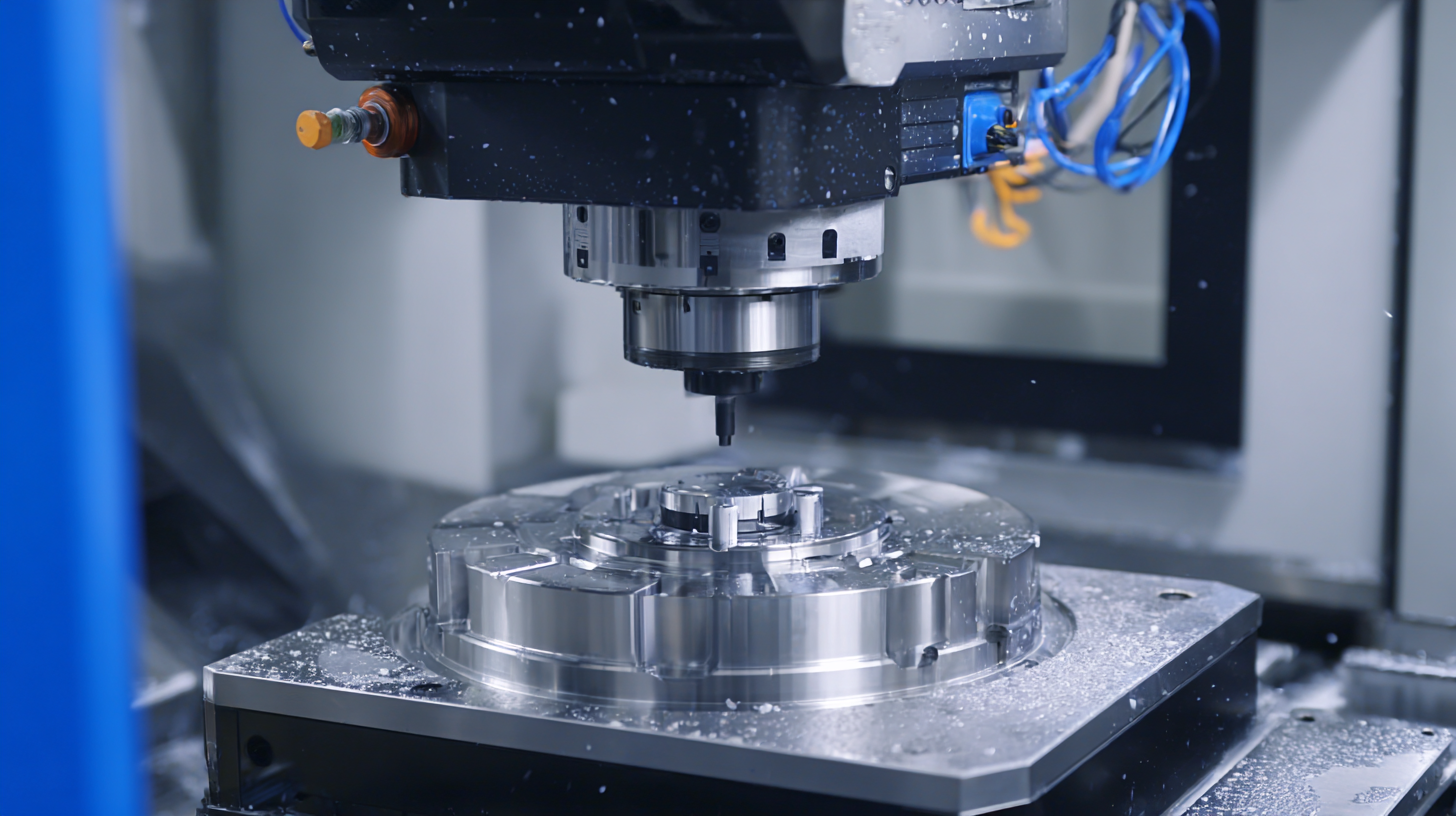

The 138th Canton Fair in 2025 is set to showcase groundbreaking innovations in CNC turning technology, highlighting its emerging applications across various industries. As digital manufacturing technologies continue to evolve, CNC turning has become an integral part of manufacturing processes, enhancing productivity and precision. The integration of smart technologies into CNC turning machines not only optimizes performance but also enables real-time data analysis, paving the way for more efficient production cycles.

Several sectors, including automotive, aerospace, and biomedical, are increasingly utilizing CNC turning for complex parts manufacturing. With the rising demand for customized solutions and high-quality components, the emphasis on precision engineering has never been greater. This shift underscores the critical role of CNC turning in facilitating advancements in product design and manufacturing efficiency, reinforcing its position as a vital technology in the future industrial landscape. As innovations unfold, the opportunities for CNC turning applications will continue to expand, driving significant growth in the machine tools market.

Impact of Advanced CNC Turning Innovations on Global Supply Chains at the Canton Fair

The 138th Canton Fair in 2025 is set to showcase the latest advancements in CNC turning technology, which are poised to impact global supply chains significantly. As China escalates its role as a leader in advanced industries, recent data indicates that the CNC machine tool market is expected to grow at a compound annual growth rate (CAGR) of approximately 5.8% over the next five years. This growth is fueled by the increasing demand for precision manufacturing across various sectors, including automotive, aerospace, and healthcare.

The integration of advanced CNC turning innovations not only enhances production efficiency but also fosters greater flexibility in manufacturing processes. According to a report by industry analysts, companies adopting these technologies can reduce lead times by up to 30% while improving production capabilities. This shift is essential for global supply chains facing pressures to optimize operations and reduce costs in a highly competitive marketplace. The innovations presented at the Canton Fair will illustrate how these advancements are reshaping the manufacturing landscape, making it crucial for industry stakeholders to engage with these emerging technologies.

Related Posts

-

How to Utilize CNC Laser Cutting Technology for Maximizing Precision and Efficiency in Manufacturing

-

Exploring Alternatives to CNC Laser Cutting Machines for Precision Manufacturing

-

7 Essential Benefits of Sheet Metal Laser Cutting for Modern Manufacturing

-

5 Best Tips for Maximizing Efficiency with CNC Fiber Laser Cutting Machines

-

Mastering the Craft of Structural Steel Fabrication A Step by Step Tutorial

-

Top Strategies for Enhancing Efficiency in Sheetmetal Fabrication Processes

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms