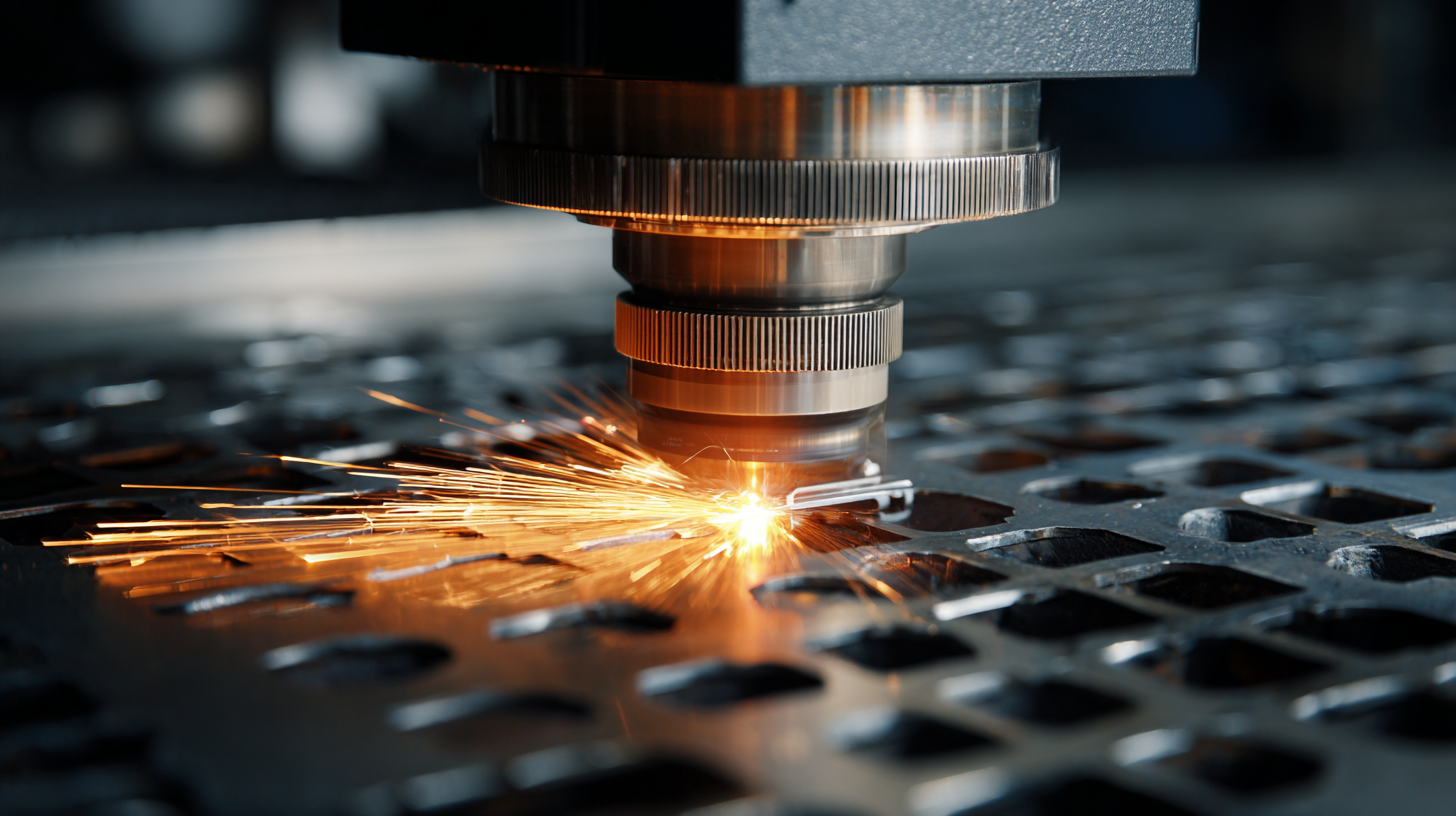

How to Utilize CNC Laser Cutting Technology for Maximizing Precision and Efficiency in Manufacturing

In the rapidly evolving landscape of manufacturing, CNC laser cutting has emerged as a pivotal technology that enhances both precision and efficiency. According to a report by MarketsandMarkets, the global CNC laser cutting machine market is projected to grow from USD 2.7 billion in 2020 to USD 3.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.1%. This growth is driven by the increasing demand for precision machining across various industries such as automotive, aerospace, and electronics, where tolerances of less than 0.1 mm are often required. Additionally, CNC laser cutting technology reduces material waste and optimizes production speeds, making it an ideal choice for manufacturers aiming to streamline their operations. By leveraging the capabilities of CNC laser cutting, companies can not only achieve superior quality in their products but also gain a competitive edge in an increasingly demanding market.

Understanding CNC Laser Cutting Technology and Its Benefits

CNC laser cutting technology is revolutionizing the manufacturing landscape, offering significant advantages in precision and efficiency. By utilizing different types of lasers—such as fiber, CO2, and solid-state lasers—manufacturers can select the most appropriate technology for their specific applications. Fiber lasers, known for their efficiency and speed, are particularly well-suited for metal cutting, while CO2 lasers excel in cutting non-metal materials like plastics and wood. This flexibility in technology type enables manufacturers to optimize their production processes according to material requirements and desired outcomes.

Moreover, the functionality of CNC laser cutting machines, categorized into semi-automatic and robotic systems, further enhances operational efficiency. Robotic laser cutting systems streamline processes by reducing manual intervention, resulting in faster cycle times and increased throughput. As industries such as automotive, aerospace, and electronics increasingly adopt these technologies, the CNC laser cutting market is expected to continue its growth trajectory.

However, the COVID-19 pandemic has caused fluctuations in demand, prompting manufacturers to adapt and innovate in order to maintain competitiveness. Understanding these dynamics is crucial for stakeholders aiming to leverage CNC laser cutting technology effectively in their operations.

Key Considerations for Selecting CNC Laser Cutting Machines

When selecting CNC laser cutting machines, several key considerations come into play to ensure that manufacturers maximize precision and efficiency. One of the primary aspects to evaluate is the type of materials the laser cutter will handle. Different lasers are optimized for specific materials, such as metal, wood, or acrylic. Understanding the intended use can significantly influence the performance and longevity of the machine.

Another critical factor is the power and speed of the laser. Machines with higher wattage typically provide faster cutting speeds and cleaner edges, but they may also come with a higher price tag. It's essential to strike a balance between your budget and the machine's capability to meet your production needs efficiently. For those aiming for entry-level options, new models now available are equipped with features such as automatic leveling, ensuring consistent results across various projects.

Tips: Consider investing in a CNC laser cutter that offers user-friendly interfaces and automation features, which can enhance precision and streamline operations. Additionally, look for providers with a solid customer support system to assist with setup and ongoing maintenance. This will not only improve your manufacturing process but also help you avoid potential downtime.

Best Practices for Implementing CNC Laser Cutting in Manufacturing

Implementing CNC laser cutting technology in manufacturing can significantly enhance precision and efficiency across various industries. As evidenced by market reports, the adoption of laser cutting machines is projected to grow, particularly with the demand for high-precision components. Data indicates that the global laser cutting machine market is expected to reach substantial figures by 2032, driven in part by advancements in fiber laser, CO2 laser, and solid-state laser technologies. These innovations allow manufacturers to switch from traditional cutting methods to more automated and environmentally friendly solutions.

Best practices for utilizing CNC laser cutting involve understanding the specific needs of the manufacturing process and selecting the appropriate technology. For instance, using fiber laser technology can provide superior cutting speeds and energy efficiency, making it an ideal choice for industries like automotive and aerospace, where precision is critical. Furthermore, implementing semi-automated and robotic systems can streamline operations, reduce labor costs, and minimize material waste. By embracing these technologies, businesses not only improve their output quality but also adapt to the ever-evolving market demands for sustainability and efficiency.

How to Utilize CNC Laser Cutting Technology for Maximizing Precision and Efficiency in Manufacturing

| Parameter | Value |

|---|---|

| Laser Power (Watts) | 500 - 4000 |

| Material Types | Steel, Aluminum, Wood, Acrylic |

| Cutting Speed (mm/min) | 100 - 3000 |

| Cut Quality (Surface Finish) | Smooth, Minimal Burr |

| Typical Applications | Signage, Prototyping, Automotive Parts |

| Investment Cost (Approx.) | $30,000 - $300,000 |

| Typical ROI Period | 1 - 3 years |

| Skill Level Required | Intermediate to Advanced |

Techniques to Enhance Precision in CNC Laser Cutting Processes

CNC laser cutting technology has revolutionized the manufacturing sector, offering unprecedented precision and efficiency. To enhance the precision of CNC laser cutting processes, manufacturers can implement several key techniques. One important method is to meticulously calibrate the laser equipment. Regular calibration ensures that the laser beam maintains its focus and intensity, which directly impacts the accuracy of cuts. Additionally, selecting the appropriate material and thickness for each specific project is crucial. Different materials respond uniquely to laser cutting, so understanding their properties can lead to better outcomes.

**Tips for Precision:**

1. Always perform a test cut on scrap material to determine the optimal settings for the specific job.

2. Utilize high-quality optics to maintain a clean and precise beam focus, which is essential for detailed cuts.

3. Monitor the cutting speed as excessive speed can lead to reduced edge quality and precision.

Another technique involves employing advanced software solutions that allow for precise design adjustments before the cutting process begins. By using CAD software combined with CAM systems, manufacturers can simulate the cutting process and identify any potential issues in the design phase, reducing errors and material wastage. Regularly updating software and utilizing the latest technology can further enhance precision and streamline operations, driving efficiency in the manufacturing process.

Strategies for Increasing Efficiency with CNC Laser Cutting Automation

CNC laser cutting technology offers a transformative approach to modern manufacturing, emphasizing both precision and efficiency. By integrating automation strategies, manufacturers can further enhance operational productivity and streamline workflows. This automation enables real-time monitoring and adjustment of cutting parameters, which ensures optimal performance and reduces material wastage. The adoption of automated systems allows for continuous processing, minimizing downtime and maximizing output, which is essential in a competitive industry.

Moreover, the advancements in laser cutting technology contribute to the growing demand for automated solutions in various sectors, including automotive, aerospace, and electronics. As companies seek to leverage cutting-edge technologies, investing in CNC laser cutting automation presents a valuable opportunity to enhance precision in high-volume production. The synergy between automation and laser cutting not only boosts efficiency but also paves the way for innovations in design and fabrication, ultimately leading to a significant shift in the manufacturing landscape.

Related Posts

-

How to Maximize Efficiency with CNC Laser Cutting in Your Manufacturing Process

-

7 Essential Benefits of Sheet Metal Laser Cutting for Modern Manufacturing

-

7 Best Laser Machine Innovations to Transform Your Manufacturing Process

-

Top Strategies for Enhancing Efficiency in Sheetmetal Fabrication Processes

-

Ultimate Guide to Mastering Metal Stamping Techniques for Your Business

-

5 Best Tips for Maximizing Efficiency with CNC Fiber Laser Cutting Machines

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms