Why Choosing the Right Welding Tools is Essential for Every DIY Project

In today's DIY landscape, the significance of selecting the appropriate welding tools cannot be overstated. According to a report from the Welding Equipment Manufacturers Association, the right tools not only ensure the quality and durability of welds but also significantly enhance safety during the fabrication process. This emphasizes the idea that the foundation of a successful welding project begins with the proper equipment.

Expert insights further illuminate this topic. John Smith, a renowned welding specialist with over 20 years of experience, once stated, "The efficiency and outcome of any welding job largely depend on the selection of proper welding tools; without them, even the simplest projects can turn hazardous." His assertion highlights the critical bridge between tool selection and craftsmanship in welding—where precision and safety converge.

In conclusion, the choices made in sourcing welding tools are paramount in achieving both desired results and maintaining safe working conditions. As DIY enthusiasts increasingly engage in home projects, understanding the importance of welding tools becomes essential for their success and safety, fostering a more skilled and responsible community of makers.

Understanding the Importance of Welding in DIY Projects

Welding is a crucial skill in the world of DIY projects, serving as the backbone for countless tasks involving metalworking, repairs, and custom fabrications. According to the American Welding Society, the welding industry is expected to grow by 6% from 2019 to 2029, highlighting the increasing importance of skilled welders in various sectors. This skill not only enhances the structural integrity of projects but also expands the possibilities for creativity and innovation in personal craftsmanship.

In DIY environments, understanding the fundamental role of welding allows enthusiasts to tackle a wide range of projects—from constructing metal furniture to building robust outdoor structures. A report by the National Center for Welding Education and Training states that effective welding practices reduce material waste by approximately 15%, underscoring its significance in budget-conscious projects. By selecting the right welding tools and techniques, DIYers can achieve professionally finished results, ensuring both durability and aesthetic appeal. With effective welding, individuals can turn their imaginative ideas into tangible creations, making the importance of this craft undeniable in today's DIY culture.

Why Choosing the Right Welding Tools is Essential for Every DIY Project

| Tool Type | Description | Key Features | Best For | Safety Tips |

|---|---|---|---|---|

| MIG Welder | A welding machine that uses a continuously fed wire electrode. | Easy to use, fast welding speed, works on thin metals. | Automotive repairs, DIY furniture. | Wear a helmet and gloves, avoid flammable materials. |

| TIG Welder | Uses a non-consumable tungsten electrode to produce the weld. | Precise control, clean welds, good for stainless steel. | Artistic metalwork, high-quality fabrication. | Ensure proper ventilation, use protective equipment. |

| Stick Welder | Uses an electrode coated in flux to create a weld. | Portable, works well on rusty metals, versatile. | Outdoor projects, heavy-duty repairs. | Avoid breathing in fumes, wear appropriate gear. |

| Plasma Cutter | Cuts through metal using a high-temperature plasma arc. | Fast cutting speed, precise cuts, minimal slag. | Sheet metal work, artistic projects. | Use in a dry area, wear protective clothing. |

Key Factors to Consider When Selecting Welding Tools

When undertaking any DIY welding project, selecting the right welding tools is paramount to achieving successful results. Key factors to consider include the type of welding process required, the materials involved, and the skill level of the individual. For instance, according to the American Welding Society, over 50% of welders primarily use MIG (Metal Inert Gas) welding due to its versatility and ease of use, particularly for thin materials commonly found in household projects. Understanding whether your project demands MIG, TIG, or stick welding can significantly influence the quality of your work.

Another critical aspect is the power source and portability of the welding equipment. A recent report by Research and Markets indicates that the global welding equipment market is expected to grow at a CAGR of 4.2% from 2022 to 2030, driven by the increasing adoption of portable welding solutions among hobbyists and professionals alike. This means that investing in a lightweight, portable welder can enhance your capability to tackle projects both indoors and outdoors, ensuring convenience and efficiency. Furthermore, personal safety gear, including gloves, masks, and protective clothing, should be non-negotiable components of your welding toolkit, considering that approximately 13% of welding accidents are due to insufficient protective measures.

Essential Welding Tools for DIY Projects

Different Types of Welding Tools and Their Applications

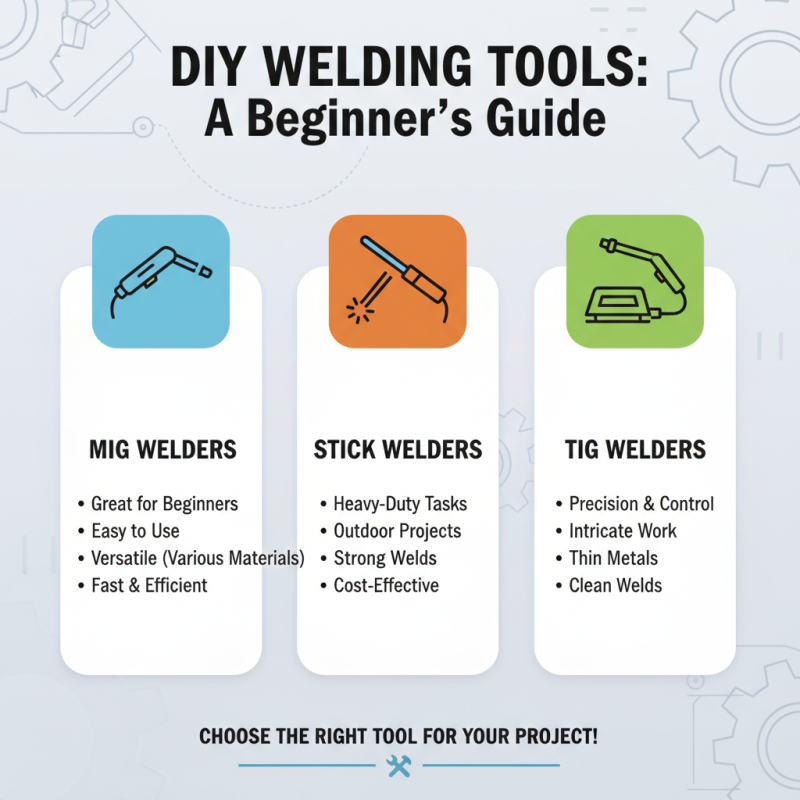

When embarking on a DIY welding project, understanding the different types of welding tools available is crucial for achieving successful results. Common tools include MIG welders, which are ideal for beginners due to their ease of use and ability to work with various materials. Stick welders, on the other hand, are preferred for heavy-duty tasks and are great for outdoor projects. TIG welders provide precision and versatility, making them perfect for intricate work, especially on thinner metals.

Tips: Before starting your welding project, make sure to select the right tool based on the material and desired outcome. It's also essential to familiarize yourself with safety protocols and gear to protect yourself during the process.

In addition to welders, other tools play vital roles in the welding process. Plasma cutters allow for clean and precise cuts, ideal for shaping materials before welding. Additionally, welders should keep a set of clamps, grinders, and protective gear easily accessible for optimal efficiency and safety. Proper tool selection and preparation can significantly enhance the quality of your project and ensure a smooth working experience.

Tips: Regular maintenance of your tools can prolong their lifespan and improve their performance. Always follow the manufacturer’s instructions and guidelines for best practices in using your welding equipment.

Safety Measures While Using Welding Equipment

When engaging in DIY welding projects, safety should always be a top priority. The use of proper safety measures is essential to protect yourself and those around you from potential hazards associated with welding. First and foremost, wearing appropriate personal protective equipment (PPE) is crucial. This includes a welding helmet with a tinted visor to shield your eyes from intense light and flying sparks, gloves to protect your hands from heat and sharp materials, and flame-resistant clothing to minimize burn risks.

In addition to PPE, creating a safe working environment is vital for preventing accidents. Ensure that your workspace is well-ventilated to avoid the buildup of harmful fumes generated during the welding process. Keeping flammable materials away from your work area is equally important, as sparks can easily ignite them. Regularly inspect your equipment for any damage or wear, and never operate faulty tools. By adhering to these safety protocols, you can significantly reduce the risk of injury and enjoy a more successful and efficient welding experience.

Tips for Maintaining and Caring for Your Welding Tools

Maintaining and caring for your welding tools is crucial to ensure their longevity and effectiveness in every DIY project. Regular inspection is a key step; check for any signs of wear or damage before starting any work. This includes examining cables for fraying, nozzles for clogs, and checking if any moving parts require lubrication. Keeping tools clean, both after use and periodically during storage, will prevent residue buildup and potential rust. Use a soft brush or cloth to remove dust and debris, and store your tools in a dry environment to protect them from moisture.

Moreover, proper storage plays a significant role in tool maintenance. Utilize toolboxes or organizers to keep your welding equipment separated and protected from physical damage. When storing, ensure that sharp components are sheathed, and heavy items are on lower shelves to prevent accidents. Conducting regular maintenance checks, like replacing worn-out tips or cleaning filters, can enhance performance and ensure safety. By prioritizing these care tips, DIY enthusiasts can extend the life of their welding tools, making them more reliable for future projects.

Related Posts

-

Unlocking the Secrets of Welding Tools: A Comprehensive Guide for Beginners

-

5 Best Tips for Maximizing Efficiency with CNC Fiber Laser Cutting Machines

-

How to Maximize Efficiency with CNC Laser Cutting in Your Manufacturing Process

-

Ultimate Tips for Using a CNC Laser Cutter for Metal Successfully

-

Ultimate Guide to Mastering Metal Stamping Techniques for Your Business

-

Ultimate CNC Machine Showdown Unveiling the Best Options for Your Manufacturing Needs

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms