10 Best Sheet Metal Prototyping Tips for 2023 to Boost Your Production Efficiency

In the fast-paced world of manufacturing, the ability to efficiently prototype sheet metal components is crucial for staying ahead of the competition. As the demand for high-quality products continues to rise, companies are increasingly turning to innovative sheet metal prototyping techniques to enhance production efficiency. In 2023, leveraging advanced technologies and best practices in sheet metal prototyping can significantly streamline processes, reduce costs, and improve overall product quality. This blog will explore the ten best tips that can help manufacturers optimize their prototyping efforts while focusing on quality craftsmanship. By adopting these strategies, businesses can elevate their manufacturing capabilities, ensuring that they remain at the forefront of the global export market, where "made in China" stands for excellence and leadership in quality.

Effective Material Selection for Optimal Sheet Metal Prototyping in 2023

Effective material selection is crucial for optimal sheet metal prototyping in 2023, particularly as industries are increasingly driven by lightweight and efficient designs. As we've seen in recent advances across various sectors, the use of innovative materials can greatly enhance production efficiency. For instance, the shift towards lightweight composite structures is not only relevant in the automotive sector but also applies to sheet metal applications, where reducing weight while maintaining strength can lead to significant improvements in performance and sustainability.

In addition, the exploration of multi-material additive manufacturing highlights the potential for integrating different properties and functionalities into a single prototype. This approach allows for greater customization and the ability to address specific challenges within sheet metal prototyping, such as defect formation and process optimization observed in traditional manufacturing methods. To align with these developments, selecting materials that offer high energy density, durability, and adaptability will become increasingly important, paving the way for more innovative and efficient production processes in 2023 and beyond.

Innovative Techniques to Reduce Lead Times in Sheet Metal Production

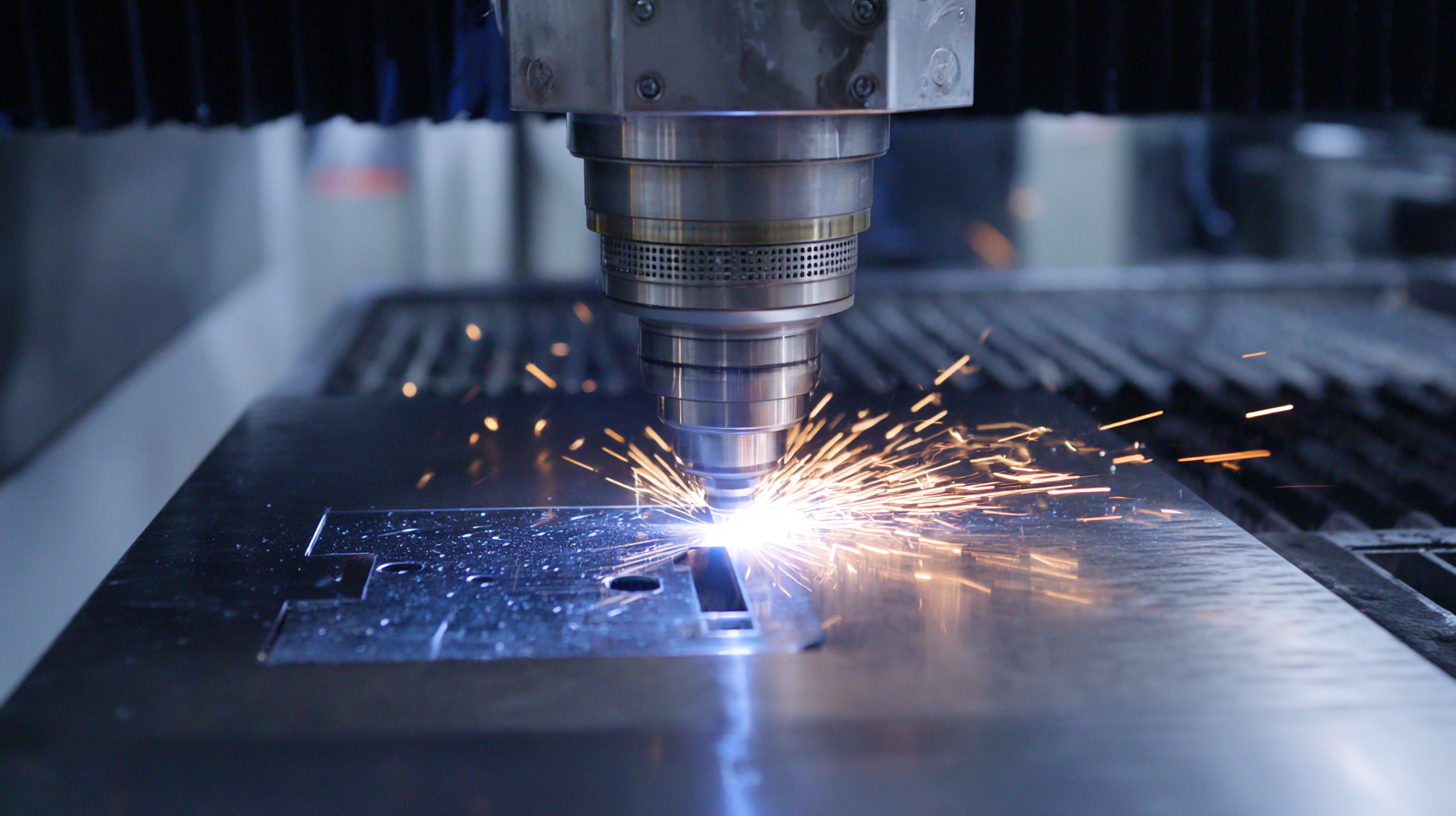

In the ever-evolving landscape of sheet metal production, reducing lead times is crucial for maintaining competitiveness and efficiency. One innovative approach gaining traction is digital sheet forming. This method eliminates the need for costly stamping tools and dies while decreasing setup times through advanced software integration. By utilizing virtual simulations, manufacturers can optimize designs and reduce production cycles significantly.

Emphasizing automation and robotics is another effective strategy. Implementing automated systems can streamline workflows, minimize human error, and increase output rates. Additionally, techniques such as wire arc additive manufacturing enable the creation of complex geometries without the limitations of traditional methods. By embracing these advancements, companies can foster a more agile production environment.

To boost production efficiency further, consider investing in employee training on new technologies. A well-trained workforce can leverage these innovations to enhance product quality and speed up the adaptation to new processes, ultimately leading to a more responsive manufacturing operation. By focusing on these strategies, businesses can not only cut down lead times but also position themselves for future growth in the sheet metal fabrication market.

Importance of Tolerance Management in Sheet Metal Prototyping Processes

Tolerance management plays a crucial role in enhancing the efficiency of sheet metal prototyping processes. Industry studies indicate that nearly 70% of manufacturing defects arise from inadequate tolerance control, leading to costly rework and extended production timelines. As manufacturers strive for precision, establishing stringent tolerance standards can significantly reduce waste and improve product quality. For instance, a report by the American Society of Mechanical Engineers (ASME) suggests that implementing effective tolerance management strategies can decrease production lead times by up to 25%, directly impacting the bottom line.

Moreover, the significance of tolerance management extends to customer satisfaction and product reliability. According to a survey conducted by the Society of Manufacturing Engineers (SME), 71% of manufacturers have noted that their customers prioritize precision and fit in sheet metal components. By investing in advanced tolerance analysis tools and fostering a culture of continuous improvement, companies can not only meet customer expectations but also innovate faster. Establishing clear tolerance specifications from the outset allows for smoother collaborations between design and manufacturing teams, ultimately leading to a more efficient prototyping process.

Leveraging Advanced Software for Enhanced Sheet Metal Design Efficiency

In the rapidly evolving world of sheet metal fabrication, leveraging advanced software tools is essential for enhancing design efficiency and boosting production outcomes. The integration of artificial intelligence (AI) into the design process is particularly transformative, providing designers with sophisticated tools for real-time data analysis and predictive modeling. By adopting AI-driven design software, manufacturers can optimize sheet metal layouts, effectively reducing waste and improving material usage while accelerating the overall prototyping cycle.

Emerging AI tools cater specifically to the needs of the automotive and HVAC sectors, streamlining operations from initial design to final production. For instance, AI algorithms can analyze customer feedback and market trends, enabling manufacturers to anticipate changes in demand and adjust their designs accordingly. Furthermore, the collaboration between major players in the HVAC sheet metal fabrication industry indicates a shift towards collective innovation, as companies join forces to enhance capabilities and broaden their technological scope. This new era promises to revolutionize production efficiency, allowing businesses to not only meet the demands of the market but also lead with innovation.

10 Best Sheet Metal Prototyping Tips for 2023 to Boost Your Production Efficiency

| Tip No. | Prototyping Tip | Description | Efficiency Boost (%) |

|---|---|---|---|

| 1 | Utilize CAD Software | Leverage advanced CAD tools for accurate design and faster revisions. | 30% |

| 2 | Prototype Early | Start prototyping as early as possible to identify design flaws. | 25% |

| 3 | Material Selection | Choose the right material for your specific application for better performance. | 20% |

| 4 | Use 3D Printing | Incorporate 3D printing for complex geometries and rapid iterations. | 35% |

| 5 | Implement DFM Principles | Design for manufacturability to simplify production processes. | 28% |

| 6 | Optimize Tooling | Regularly update and maintain tools for efficiency and precision. | 22% |

| 7 | Feedback Loops | Establish systematic feedback from production to refine designs. | 24% |

| 8 | Lean Manufacturing | Apply lean principles to reduce waste and improve workflow. | 30% |

| 9 | Automate Processes | Incorporate automation to enhance production speed and accuracy. | 40% |

| 10 | Training & Development | Invest in training staff to utilize technology and enhance skills. | 27% |

Sustainable Practices in Sheet Metal Prototyping for Future-Ready Manufacturing

In the context of sustainable practices in sheet metal prototyping, manufacturers must adapt to the increasingly eco-focused landscape of production. As industries respond to global sustainability mandates, report findings indicate that adopting advanced automation and more efficient intralogistics can significantly reduce waste and energy consumption. For instance, using computer numerical control (CNC) technologies in sheet metal processes can minimize material scraps by up to 30%, thereby reinforcing a solid foundation for future-ready manufacturing practices.

Moreover, the integration of next-generation materials, akin to those found in the evolving textile industry, offers promising opportunities for efficiency and sustainability in sheet metal prototyping. It has been projected that industries embracing innovative materials and techniques could improve production timelines by approximately 20%. This shift not only caters to the growing demand for sustainability but also positions companies at the forefront of a rapidly changing market. As such, incorporating these sustainable practices can enhance productivity and bolster a brand's reputation in a competitive landscape focused on environmental responsibility.

Sheet Metal Prototyping Efficiency Metrics for 2023

Get your project done the Right way

7:00am - 5:00pm

- Copyright2025 © Tri-State Fabricators

- Accessibility

- Privacy Policy

- Terms